Well, now. It's kind of a sad morning as we are packing up and have to load the vehicle. Yes, I'm whining a bit, but I AM sad that the retreat has ended. I pack up my stuff in the room and head into the center. Jen's quilt is up on the wall -- borders on. I have no idea what time she went to bed but has to be oh so tired.

Well, now. It's kind of a sad morning as we are packing up and have to load the vehicle. Yes, I'm whining a bit, but I AM sad that the retreat has ended. I pack up my stuff in the room and head into the center. Jen's quilt is up on the wall -- borders on. I have no idea what time she went to bed but has to be oh so tired.

We all get our areas packed up and there is just SOOO much. Consolidate, consolidate, consolidate. Once we are all packed and things are out of the room, there is a brief moment of relaxation for some. This has been a fabulous time and we are in unison that we wish to return. A Facebook group just for Doan Girls Retreats has been created and it is for those who have shared this amazing experience. I cannot express strongly enough how inspiring and genuine they all are. The love they have for each other shows in all they do and how they work with others in the company. We really don't have a single complaint to share. This experience has been OVER THE TOP.

Gwennies fun time -

Remember the cathedral window top --- it's done and lovely.

The room just look so sad now.

The clown car is LOADED - OMG, it's loaded. Jen says there is still 6 inches so we're all good. It's time to head west a bit. Jen has a flight this afternoon out of Kansas City, but we have a stop to make along the way. I've found something to explore.

Hahahaha --- fooled you. We are on our way back into Hamilton. Jen wants to drop her quilt off for quilting and we have a few items to add - there's always a daily deal to pick up, right?

Today's deal was thread --- grabbed it and helped others with their items and we are on the way again. First up is the World's largest spool of thread.

It is in the front of the Missouri Star Quilt Museum, which we planned on visiting today. However, they are not open for several hours still. Drat. We just assumed if the shops were open, it would e too. Another time.

In front of it is the crazy, fun stretch limo. Look close. I heard about a shuttle, but don't think this was it.

We are finally on the road when I get a message from the center that we left a bag. Back we go. It's funny cos Gwen had a feeling something was missing. She was right. NOW, we are on the road again. About an hour away is my treasure I've found.

Welcome to the Watkins Woolen Mill State Park. Be ready for oh so many pictures as it was amazing and I will educate you against your will.

A little back ground for ya: This is the Bethany Plantation. In 1839 Waltus Watkins, a Kentucky native, moved his family to the northeast corner of Clay county, Missouri, and established a small livestock farm. By 1870, the Bethany Plantation was nearly 1,200 acres, with Watkins' total landholdings in Clay and Ray counties at 3,600 acres. This agricultural and industrial enterprise included the home farm and a number of smaller surrounding sections. Watkins, like most farmers of his day, practiced diversified farming. He raised shorthorn cattle, Missouri mules, horses, swine, sheep and poultry, grew various grain crops; and planted extensive orchards. His plantation expanded to include a brick kiln, gristmill, sawmill, blacksmith shop, dairy, fruit dry house, ice house, barns and other farm buildings, and housing for farm and mill workers. He also marketed the services of his mills, kiln and blacksmith shop to people in the area.

We arrive just as the tour group left, but the lovely lady at the counter finds us another guide and we are out the door and walking to the mill in no time. It is simply gorgeous here. The views are incredible and I just want to stay forever, but it's dang hot and humid so I want to stay and see it but not necessarily hang out outside right now.

When the woolen industry reached Missouri in the 1850s, Watkins decided to take advantage of his early training in Kentucky textile mills and built the Watkins Woolen Mill in 1860. The three-and-a-half story mill was constructed of brick handmade at the site and supported by timbers cut from his land. Watkins Mill was a medium sized factory. But, for Missouri it was large, three times the average size. It produced a wider range of goods than most mills its size and had a trade radius of over 70 miles. The mill building resembles mills built in the 1830s and 1840s. Architecturally, it was quite out of date at the time it was built and did not have many of the features common in the newer eastern mills.

We meet our guide outside the mill and I'll share what I know at this point. I had read that the mill was completely operational and, after the father died, the sons just didn't want to continue it so they closed the doors and left it intact. I'm super excited to see what is inside.

Everything on site has a purpose and a past.

This is a rendering of what the above picture represents today -

In we go --- first to where the power for the whole building comes from. Watkins purchased most of his equipment from the leading textile machinery manufacturers. Machinery was shipped from other factories in Pennsylvania. Sometimes, as with the washing machine and the willower, he bought second-hand. Watkins kept up with technological changes and up-dated and expanded the mill in 1863 and again in 1868. The dye operation was enlarged in the 1870s. Not all of the equipment was factory made. Watkins hired several talented carpenters who built simpler apparatus like the dye vats and the warping mill. A highly skilled machinist was employed to maintain and repair the mill machinery.

16' wheel - she does it all.

There is a spring under the grate that still has clear water in it.

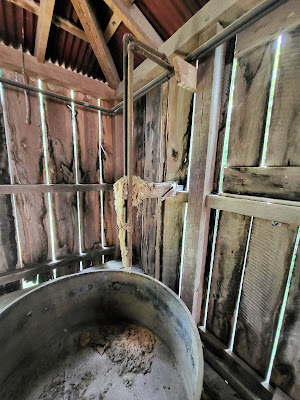

This area was used for cleaning the wool.

At one time, the area held several tanks.

Back outside - a bunny stops to say howdy.

A look back so you can see where we have been - not really in the mill yet. Watkins Mill operated in the Rhode Island, or English manner where several members of a family might work together in the mill. At its peak, Watkins Mill employed forty people; twenty five men, ten women and five boys. Being one of the first mills in the are, there were no trained machinery operators here. Most of the people who worked in the mill came to Missouri hoping to buy land and build a home for their family.

Into the mill --- the first stop is where the sheep were sheared. Yep - INSIDE the mill.

Sidebar - across the way is a broom making set-up that was brought in from another building.

Checking out the various types of wool that were shorn here - Cotswold and Merino.

The next step is the processing of the wool after it has been washed. These large tumblers start beating it.

It's dumped out of the tumbler and put onto this bed which moves it through another shaker/shredder/thingy. I'm sorry, it's hard to remember all the parts.

And this comes out behind.

From here - it goes onto giant carding machines to further soften the wool and remove ANY leftover impurities.

When it leaves this machine - we have these rovings.

Which are loaded onto this machine. Notice the LARGE spools on the drum - there are several of them. Let the spinning begin.

Those spools, when filled are moved to this machine - and it starts pulling fine threads onto smaller spools. There are two machines here - back to back.

And two more further down - back to back. ONE worker handled each machine. ONE. By today's standards, working in the woolen mill was hard and uncomfortable. For the 19th century, it was a good job. The pay was high and the workdays were short. Mill workers did face several difficult conditions: heat, noise and threat of injury, all necessary conditions of the job.

A little closer in.

Next - the spools move on.

This creates ANOTHER large spool - on the floor is an example. The workday in Watkins Mill started at 11 hours a day in the 1860 but was reduced to 10 hours in the 187s. The mill ran as few as three to as many as seven days a week depending on the volume of orders. The mill generally operated full time from March through October; production slowed down in November. On Dec. 24, the mill usually closed for one or two weeks or until spring shearing if there was a wool shortage. When orders were slow, the mill closed down until new orders came in, usually for a day or two.

Which then gets loaded onto THIS machine - can you guess what it is?

A loom!! And the weaving process begins. Many woolen manufacturing jobs required years of training. Trained mill operatives made much higher wages than laborers and farm workers. As machinery improved, the level of skill required to do some of the jobs decreased and wages dropped. The Watkins paid their mill workers a good wage through the 1880s.

Not all was woven. Some became yarn. This is the ply-twister machine.

This one is doing yarn. The Watkins provided some of their workers with rent-free housing on Smokey Row, a line of about a dozen small two-room dwellings located along the state highway at the entrance to the farm. Preference was give to married workers with families. Many of the single men boarded with other mill employees with neighborhood homes. Several boarded with the Watkins family. They also paid the boarding houses according to how many meals each employee ate. The employees were not charged for their board.

Which then goes onto this skeiner and the person at the end removes a bundle - watch the red one.

Which is then put onto a hanker and makes the skeins. Check out the hole in the floor. It was created by a boot that stood there for YEARS making skeins.

Watch it in process --- it goes quick.

The skeins are then put onto a scale, weighed and boxed up for shipment.

Now - back to the woven fabric. When it was woven, it was left to set. Its ROUGH.

Up close workings of the large looms.

From here --- it gets treated again. And hung.

Then put through the filling mill - the base holds water. At least there is a view and some air up here. No electricity in this mill makes for a warm tour.

Hung some more -

This is also the dying area (which would have taken place much earlier in the process, but we haven't been in this room yet). One thing we noticed was that it wasn't very streamlined for the process. The wool gets moved from place to place and floor to floor A LOT.

Pieces of wool are sewn end to end and rolled together here.

Oh for the love of all that is good -- I was too busy taking pictures here and missed what these were used for. Help!

The baler then compresses the fabric for easier shipping.

Sidebar - there is also a lathe shop in here that was moved from somewhere else.

The fabric now is either shipped out or goes to the general store - on site. A lot of trading took place so many different items could be pick up here.

I'll share some of the signs from the museum here -

This was cool too --- in the store.

And that's the mill part of our tour. The house is next but I wanted to share one last item. I mentioned above that boys worked here. In the 19th century, most children worked. Working class families had to hire out their children to businesses, farmers, and factories. Most boys started working in the mills at the age of 10. These children were learning a trade and would be able to support themselves by the time they were 16 and officially listed as adult workers. There were also black workers on the farm as as cooks, but there are no records of any blacks working in the mill.

Off we go to the house -

Our guide is waiting as we ran a bit late in the mill with all of our questions. I am not going to share a bunch of information on the house - so just enjoy the pics. If it's cool or unique, I'll type.

The original homesite -- 7 people lived in this space - one floor.

Inside the Ice House - soooo deep.

Used to cut the blocks of ice on the river.

Into the house - entryway with hand-made staircase.

Mr. Watkins stand-up desk.

Yep - always a machine around.

Upstairs view - feels so good. This house does not have electricity running either.

The family parlor -

Downstairs was one bedroom we didn't see. This stairwell leads down to it or up from it, whichever you prefer. It was Grandma's room downstairs and went up to the nursery.

Original walls which have been protected.

A loom in a room. Hahaha

The kitchen is a separate building. Very common.

The smokehouse -

The dehydrator --- biggest one I've ever seen. These were peach orchards, if I remember right.

That's all I got for the house --- soooo many interesting stories and I would highly recommend a visit. BOTH tours cost $5 combined.

The infamous sheep.

A quick stop in the museum at the end --- these are items discovered when the privy was dug out.

A loom that one could operate to get the feel of how they work. I also liked that they showed the turning points in society and the sewing machine was one. Invented in the 1840s in response to the growing availability of manufactured fabrics, sewing machines were widely available by the 1860s. Like most other labor saving inventions, the sewing machine did not really save time; it made it possible to do more sewing in the same amount of time - so clothing became much more elaborate and complicated. The sewing machine led to the notorious garment factories known as sweat shops, where women and children labored for long hours in miserable conditions for very low wages. Yet the sewing machine also provided poor widows and single women with a notable new choice; even those who were not expert needlewomen could now work as seamstresses in their own homes, instead of having to become poorly paid house servants, factory workers, or (if they could read) school teachers. The idea of selling goods on credit was first used by a sewing machine manufacturer as a way to market his machines to individuals and was the primary reason for its rapid acceptance in American homes.

This is a cool look into the mill we were in - hard to get a good picture with the lights though. If you want even more information about this place -- here is an informative

LINKThat's it for the Watkins stop. Not this day however. We are back on the road, looking for food, which is found. About this time there is a glitch in the plans and while we enjoy lunch, Jen is on the phone attempting to figure things out. Her flights are so messed up that she can't get there tonight and that means getting stranded in SLC at midnight and hoping her flight goes well the next day --- with no way home. Her family is already in Montana and they are trying to work it all out. We just sit in the restaurant and wait to see our next move. No need to go to Kansas City if we are not dropping her off.

It's official -- the plans have changed and she is with us for the duration. I'm sad for her, but happy that we all have more time with her. We are re-routed and she has found some retail therapy to help out. Literally --- our next stop is Quilting is My Therapy in Liberty, MO. Let's do it.

It's a cute little shop that is about to close so we don't have a ton of time.

However, THAT doesn't stop us from having fun. They have Angela Walters fabric and I haven't seen it in the metroplex, so I pick up a backing. THEN I spot an Allison Glass kit that I love and add it. Toss in a fun pattern and I'm stopping. We are about done for today. Gwen has found a hotel near and we are aiming that direction. Tomorrow is another day. Oh -- check out the weird mushroom along the road. It's a Giant Morel Mushroom. Okay.

A room and dinner. My eyes are WAAAY bigger than my stomach tonight, but it is sooo good. That's it for today. See ya in a.m.

Well, now. It's kind of a sad morning as we are packing up and have to load the vehicle. Yes, I'm whining a bit, but I AM sad that the retreat has ended. I pack up my stuff in the room and head into the center. Jen's quilt is up on the wall -- borders on. I have no idea what time she went to bed but has to be oh so tired.

Well, now. It's kind of a sad morning as we are packing up and have to load the vehicle. Yes, I'm whining a bit, but I AM sad that the retreat has ended. I pack up my stuff in the room and head into the center. Jen's quilt is up on the wall -- borders on. I have no idea what time she went to bed but has to be oh so tired.

We arrive just as the tour group left, but the lovely lady at the counter finds us another guide and we are out the door and walking to the mill in no time. It is simply gorgeous here. The views are incredible and I just want to stay forever, but it's dang hot and humid so I want to stay and see it but not necessarily hang out outside right now.

We arrive just as the tour group left, but the lovely lady at the counter finds us another guide and we are out the door and walking to the mill in no time. It is simply gorgeous here. The views are incredible and I just want to stay forever, but it's dang hot and humid so I want to stay and see it but not necessarily hang out outside right now.

However, THAT doesn't stop us from having fun. They have Angela Walters fabric and I haven't seen it in the metroplex, so I pick up a backing. THEN I spot an Allison Glass kit that I love and add it. Toss in a fun pattern and I'm stopping. We are about done for today. Gwen has found a hotel near and we are aiming that direction. Tomorrow is another day. Oh -- check out the weird mushroom along the road. It's a Giant Morel Mushroom. Okay.

However, THAT doesn't stop us from having fun. They have Angela Walters fabric and I haven't seen it in the metroplex, so I pick up a backing. THEN I spot an Allison Glass kit that I love and add it. Toss in a fun pattern and I'm stopping. We are about done for today. Gwen has found a hotel near and we are aiming that direction. Tomorrow is another day. Oh -- check out the weird mushroom along the road. It's a Giant Morel Mushroom. Okay.

No comments:

Post a Comment